We specialize in small setscrews.

Akiruno-city Tokyo JAPAN

Setscrew and driver blade width

The setscrew goes into the female screw with a flat-blade screwdriver. If the blade width of a flat-blade screwdriver is larger than the hole diameter of the female screw, the inside of the female screw will be damaged. Therefore, please be careful about the relationship between the nominal diameter of the setscrew and the blade width of a flat-blade screwdriver.

For example, there are 0.9mm, 1.2mm, 1.8mm, and 2.3mm, which are standard blade widths for flat-blade screwdrivers, in the No.207 precision screwdriver set of 6 precision screwdrivers of Japanese manufacturer "Vessel".

However, No.207 is now discontinued, and its successor is the 6-piece No.TD-56, which has a slightly high-class feel.

There is a nominal diameter of the setscrew suitable for each, so it is described below.

| Coarse Thread | Inner Diameter of female screw (mm) |

Fit blade width (mm) |

Its blade thickness (mm) |

Slotted width of DELscrew (mm) |

|

|---|---|---|---|---|---|

| Nominal Diameter | Pitch (mm) |

||||

| M1 | 0.25 | 0.75 | (0.7) | 0.2 | 0.28 |

| M1.2 | 0.25 | 0.95 | 0.9 | 0.2 | 0.30 |

| M1.4 | 0.3 | 1.10 | 0.35 | ||

| M1.6 | 0.35 | 1.25 | 1.2 | 0.25 | 0.35 |

| M1.7 | 0.35 | 1.35 | 0.35 | ||

| M2 | 0.4 | 1.60 | 0.35 | ||

| M2.3 | 0.4 | 1.90 | 1.8 | 0.3 | 0.50 |

| M2.5 | 0.45 | 2.10 | 0.50 | ||

| M3 | 0.5 | 2.50 | 2.3 | 0.35 | 0.50 |

If you read from the above table, you can see that the M1 setscrew can be used by reducing the blade width of 0.9 mm to 0.7 mm.

"Vessel" has a flat-blade screwdriver called precision screwdriver No.TD-51 (Slotted 0.7), which is sold separately, but the dimensions are 0.7 mm in blade width x 0.15 mm in blade thickness. It can be used as it is for M1 setscrew.

When you assemble, you may want to attach a small setscrew to the tip of a flat-blade screwdriver so that it will not fall (without using magnetism). For that purpose, it is necessary to match the blade thickness of the screwdriver with the width of the sliding groove of the setscrew to be used. It is also better to adjust the angle of the blade that enters the sliding part.

In addition, the width of the sliding groove of the setscrew must be highly accurate, and the depth must be constant.

Three Benefits of DELscrew

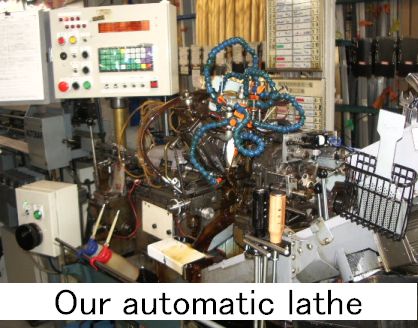

Our micro setscrew (DELscrew) which is manufactured by modified our self-developed Cam type automatic Lathe with the microcomputer-control has three featuring points.

No.1 benefit in choosing DELscrew

We provide high quality a setscrew, a precision setscrew, and good technical service to customers.

The reason is, all of our screw is manufactured by microcomputer control Cam type Automatic lathe with cutting work using a special cutting tool,

a threading chaser (cemented carbide) for screw thread.

Basically, at other companies Cam type they have, a screw thread is manufactured using die (steel),

and it causatively often happened defective products like incomplete thread and a deficiency of screw thread.

We provide high quality a setscrew, a precision setscrew, and good technical service to customers.

The reason is, all of our screw is manufactured by microcomputer control Cam type Automatic lathe with cutting work using a special cutting tool,

a threading chaser (cemented carbide) for screw thread.

Basically, at other companies Cam type they have, a screw thread is manufactured using die (steel),

and it causatively often happened defective products like incomplete thread and a deficiency of screw thread.

Our cemented carbide cutting tool is more hard than Die steel, and it has resistance to abrasion,

also it reduce the rate of deterioration of the effective diameter.

Based on the above result, we are keeping manufacture to provide our customer high quality without the occurrence of defective product.

Our cemented carbide cutting tool is more hard than Die steel, and it has resistance to abrasion,

also it reduce the rate of deterioration of the effective diameter.

Based on the above result, we are keeping manufacture to provide our customer high quality without the occurrence of defective product.

No.2 benefit in choosing DELscrew

Manufacturing processes and cutting tools to provide high production flexibility by our Cam type.This Cam type automatic Lathe was modified to SAIDA specification,

which the ultimate tool for creating mass production. It is a key difference from CNC.

The ability can be produced a single steel setscrew in less than two seconds,on 24-hours operation, a production rate of up to 35,000screws per day is possible.

Our Cam-type automatic Lathe have enough flexibility to meet your needs.

Manufacturing processes and cutting tools to provide high production flexibility by our Cam type.This Cam type automatic Lathe was modified to SAIDA specification,

which the ultimate tool for creating mass production. It is a key difference from CNC.

The ability can be produced a single steel setscrew in less than two seconds,on 24-hours operation, a production rate of up to 35,000screws per day is possible.

Our Cam-type automatic Lathe have enough flexibility to meet your needs.

No.3 benefit in choosing DELscrew

Achieve a low price and we can also produce stable products by our refined Cam type automatic Lathe. Since establishment in 1965, over many years of experience in the industry and we continue providing slotted screws. For example, to make a thread by a dies is difficult which number of screw is small. Our screw is easy to make it the screw thread because it is processed by special cutting tool and remodeling Cam type automatic Lathe in-house. Incomplete thread is processable within 1 thread.

Our Cam-type Automatic Lathes of Microcomputer Control

![]()

Our manufacturing machines are Cam-type automatic lathe of headstock movement-type.

Breakdown of Cam-type Automatic Lathes of Microcomputer Control (as of Sept. 3, 2020)

- Precision grade --- 19 machines

- Normal grade ------ 17 machines

We had remodeled the old cam-type automatic lathes, and so now, our cam-type automatic lathes control the movement of the camshaft by a microcomputer. Therefore, our cam-type automatics lathes can do the manufacture of screw thread by the threading chaser in the same way as NC type automatic lathes.

The best feature of our manufacturing technology is small precision parts can be manufactured efficiently. We remodeled old cam-type automatic lathes, into new cam-type automatic lathes of microcomputer control. Our cam-type automatic lathes, a thread of screw is manufactured by the threading chaser by micro computer control.

Therefore, screw thread is a high quality. Our cam-type automatic lathes have mechanism of pick up for screw slotting. We can collect all the small parts which manufactured, because our cam-type automatic lathes pick up a part.

The NC type automatic lathes are the excellent machines for making the complex processing. For example, it can process the side hole by drill, the internal thread by tap, and the D-cut by end milling. The old days, complex shape's parts were manufactured by more than one machine, but now, they can be manufactured by one NC type automatic lathe.

The cam-type automatic lathes cannot do the manufacture of complicated parts such as the above. But, they manufacture the simple shape parts in shorter times than the NC-type automatic lathes. They are the very superior machine to manufacture a lot of parts with a low cost.

From old days, the general-purpose lathes process a screw thread by the threading chaser by the master screw and the combination gears. However, current NC-type automatic lathes process a screw thread by the threading chaser by computer control.

In general cam-type automatic lathes, the manufacture of screw thread by the threading chaser is impossible.

Our NC-type Automatic Lathes

NC-type Automatic Lathes (Click on the right photo to see it larger)

| Maker | Model | Unit | Photo |

|---|---|---|---|

| TSUGAMI | B012(c)-3 | 1 |

|

| TSUGAMI | B0124-3 | 2 |

|

| Star | RNC-16 | 3 |

|

Our Machine Tools

(Click on the right photo to see it larger)