We specialize in small set screws.

Akiruno-city Tokyo JAPAN

Keep the advantage of Cam-type Automatic Lathe

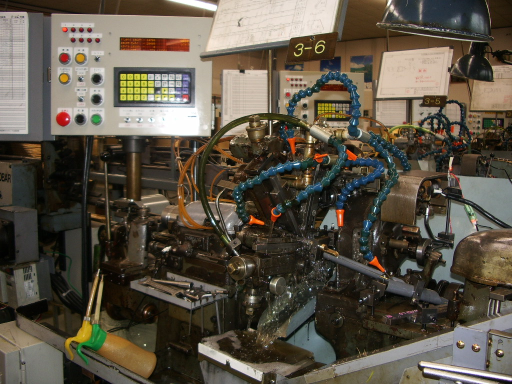

As a specialized manufacturer of small set screws, we have manufactured our own microcomputer-controlled cam-type automatic lathe that cuts threads in order to deliver high-quality and cheap set screws to the world.

Incorporating the advantages of Cam-type automatic lathes, the disadvantages of Cam-type have been eliminated. In addition, the advantages of NC-type automatic lathes have been incorporated and the disadvantages of NC-type have been eliminated. Our microcomputer-controlled Cam-type automatic lathe is the only automatic lathe in the world that pursues efficiency and ease of use.

The microcomputer-controlled Cam-type automatic lathe makes the best use of the advantages of the Cam-type for machining products.

- See the photo of the microcomputer-controlled Cam-type automatic lathe on the right. Parts are manufactured on such a small automatic lathe. Compare with the yellow oil bottle at the bottom left. (Click the photo to enlarge)

- Due to the Cam-type automatic lathe, the time required to manufacture one part is short.

- Among the Cam-type automatic lathes, it is a particularly small automatic lathe. It is not rigid, but it moves quickly, and one brass part or screw with a simple shape is manufactured in 1.5 seconds.

- If you watch the video on the upper right, you can get a better understanding.

Include the advantage of NC-type Automatic Lathe

The microcomputer-controlled cam-type automatic lathe incorporates the advantages of NC-type automatic lathes into the machining of cut products.

The microcomputer-controlled Cam-type automatic lathe developed by a specialized manufacturer of small set screws

incorporates the speed of machining of Cam-type automatic lathes and the easy handling of NC-type automatic lathes

into the machining of products.

We have made it possible to achieve both improved component accuracy and improved production efficiency, which has never been seen before. The photo on the right is an operation panel made in house with a handmade feel. (Click the photo to enlarge)

- The spindle rotation speed (rpm) of the automatic lathe can be freely set during machining. By slowing down the spindle rotation (2,000 rpm) during thread cutting and increasing the spindle rotation (6,000 rpm) during normal cutting, the optimum spindle speed (rpm) can be achieved during cutting. Therefore, the manufacturing efficiency of screw parts will increase.

- The rotation speed of the camshaft can be freely changed during machining. In the non-cutting process (rapid movement), the camshaft can be rotated quickly (60 rpm or more), so the efficiency of manufacturing metal parts and screws is greatly improved. Combined with the above two advantages and the original speed of the cam type, it has become possible to shorten the time required to manufacture one part. It is possible to manufacture one small and simple brass part or screw in one second.

- The camshaft rotation speed setting can be easily changed on-site during cutting. On-site technicians can upgrade to optimal cutting feed and rapid movement while observing the state of cutting.

-

Since screw processing is a cutting process using the cutting tool (the feature of chasing processing),

it is excellent in the sophistication and stability of screw quality and accuracy when manufacturing screws.

Unlike screw production by cutting die processing, thread chipping and unprocessed defects in the threaded part do not occur,

and the screw depth is also determined exactly.

However, when making a screw with a head, the limit is cutting with about 3 threads.

On the other hand, when making a screw with a head, we are good at cutting with one thread. Unlike die machining, there are no thread chips or unprocessed threads, and the screw depth is perfectly determined. -

Since the threaded part is machined with a threaded blade tool, non-standard screws can be easily manufactured.

- By changing the process program, it is possible to manufacture non-standard screw pitches.

- By changing the angle of the cutting tool, it is possible to manufacture non-standard thread angles such as 50 degrees, 70 degrees, and 90 degrees.

- As for the screw diameters, any combination of non-standard screw outer diameter, non-standard screw effective diameter, and non-standard screw root diameter can be manufactured.

- In addition to metric screws, we can also process and manufacture unified screw thread and sewing machine screws. However, the limit is M4 or less for brass, M3 or less for steel, and M2 or less for stainless steel.

- We can easily change the part dimensions by rewriting the correction value.

Crush the demerit of Cam-type Automatic Lathe

The microcomputer-controlled Cam-type automatic lathe eliminates the disadvantages of general Cam-type automatic lathes.

-

The microcomputer-controlled Cam-type automatic lathe can freely set the rotation speed of the spindle

from 100 rpm to 8,000 rpm for each process.

- In a general cam type automatic lathe, the rotation speed of the spindle cannot be set for each cutting process.

- It is not possible to obtain the optimum spindle rotation speed for each process, such as the cutting process and thread cutting process.

-

The microcomputer-controlled cam-type automatic lathe can freely set the rotation speed of the camshaft

from 1 rpm to 80 rpm for each process.

- With a general cam-type automatic lathe, the rotation speed of the camshaft cannot be set for each cutting process.

- It is not possible to achieve the optimum camshaft speed during processing.

- It is not possible to optimally upgrade the cutting feed for each process while observing the state of cutting at the site.

-

The microcomputer-controlled Cam-type automatic lathe confirms the return position

with a microcomputer, ensuring the stability of component quality.

- In a general Cam-type automatic lathe, the drive is performed by the cam, but the return is performed only by the spring, so it lacks safety and stability.

- Where parts are required for accuracy, quality will be poor unless they are returned to the correct position.

-

The microcomputer-controlled Cam-type automatic lathe is "chasing manufacture (screw cutting with a tool)" for both male and female threaded parts,

so the quality and accuracy when manufacturing threaded parts are assured.

- With a general Cam-type automatic lathe, thread cutting is only done using dies (for male threads) and taps (for female threads).

- Since a general Cam-type automatic lathe cannot perform "chasing manufacture (screw cutting with a tool)" due to its mechanical structure, it lacks stability in screw quality and accuracy.

- In general Cam-type automatic lathes, the screw depth has varied, which may cause thread chipping and unprocessed defects in the threaded part.

Crush the demerit of Cam-type & NC-type Automatic Lathe

The microcomputer-controlled Cam-type automatic lathe eliminates the disadvantages of the Cam-type and NC-type.

-

In the Peterman (spindle movement) type automatic lathe,

both the cam type automatic lathe and the NC type automatic lathe have the same drawbacks

(the product may have a shorter overall length).

This is the same for threaded parts and general parts.

It occurs during the process described below.- Open the chuck of the spindle.

- The headstock (with spindle) returns.

- Close the chuck of the spindle.

- In a Peterman (spindle movement) type automatic lathe, these three steps are absolutely necessary when machining one part.

-

During these three steps, the material is pushed from behind and pressed against the cutting off tool.

Sometimes the following things happen.- Open the chuck of the spindle.

-

The headstock (with spindle) returns.

At this time, the material may be remains slightly step away from the parting tool.

And continue to the next process. -

Close the chuck of the spindle.

If this is the case, the overall length of the product will be shortened by the distance from the cutting off tool, resulting in a defective product.

- Our microcomputer-controlled Cam-type automatic lathe monitors the contact between the material and the cutting off tool with a computer to prevent the occurrence of a full-length defect.

Mechanical & Control & Process Design

As the specialized manufacturer of small set screws, we design and manufacture microcomputer-controlled Cam-type automatic lathe according to the unique processing process required for screw processing. Therefore, it is possible to provide highly accurate and cheap set screws.

In order to create such a unique microcomputer-controlled Cam-type automatic lathe, we have refined our "mechanical design" and "control design (computer control)" technologies as a specialized manufacturer of small set screws.

In addition, we also do all the "process design", which is generally called "cam design", in-house, and feed back the process contents while observing the processing status of set screws and parts on site to create a better processing process.

Supported by the three pillars of technology as a metal parts manufacturer, "mechanical design", "control design" and "process design" we continue to seek "differences" from other automatic lathe factories.

We will continue to study daily with the aim of further improving our design technology.