We specialize in small set screws.

Slotted set screw's nominal diameters are

M1,

M1.2,

M1.4,

M1.6,

M1.7,

M2,

M2.3,

M2.5, and

M3.

Slotted set screw's overall lengths are

1mm,

1.1mm,

1.2mm,

1.3mm,

1.4mm,

1.5mm,

1.6mm,

1.7mm,

1.8mm,

2mm,

2.5mm,

3mm,

4mm,

5mm and

6mm.

Slotted set screw's tip shapes are

flat point,

cone point,

oval point.

SAIDA Manufacturing Co. Ltd.

Akiruno-city Tokyo JAPAN

Akiruno-city Tokyo JAPAN

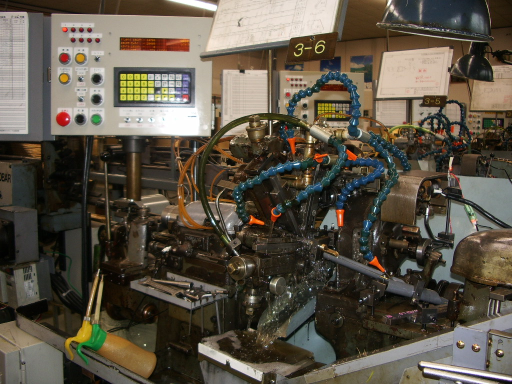

Our Cam-type Automatic Lathes

- Our microcomputer controlled Cam-type automatic lathe (normal class) is a cam-type automatic lathe that controls the rotation speed and direction of the camshaft and the rotation speed and direction of the spindle.

- Our microcomputer controlled Cam-type automatic lathe (precision class) is a cam-type automatic lathe that controls the rotation speed and direction of the camshaft, the rotation speed and rotation direction of the spindle, the forward / backward movement of the headstock.

- While retaining the good points of the Cam-type automatic lathe, it incorporates the good points of the NC-type automatic lathe and further compensates for the disadvantages of the Cam-type automatic lathe.

-

For details, please click here for "Automatic Lathes of Microcomputer Control".

The photo on the upper right is the main body of the automatic lathe,

and the photo on the lower right is the operation panel.

(Click the photo to enlarge)

Advantages and Disadvantages of microcomputer controlled Cam-type automatic lathes

- --- Advantages ---

-

Since the basic structure is a Cam-type automatic lathe,

simple parts have a short machining time and are one of the elements that enable the supply of cheaper parts.

(The production time of 1 piece is 1.5 seconds ~) - Screw thread can be manufactured with dies (tap) or can be manufactured in chasing with the cutting tool.

- The rotation speed of the spindle can be freely set to the optimum rotation speed for the machining process. As a result, the machining time is further shortened, which is also one of the factors that make it possible to supply cheap parts.

- The rotation speed of the camshaft can be set to any speed and optimum speed for both cutting and non-cutting processes. As a result, the machining time is further shortened, which is also one of the factors that make it possible to supply cheap parts.

- By confirming that the computer has returned to the place on the mechanism that returns with a spring, it is possible to manufacture parts with high safety, security, and accuracy.

- Since products are picked up by a pickup device, small products can be separated from swarf, resulting in a high product recovery rate, which is also one of the factors that makes it possible to supply cheap parts.

- --- Disadvantages ---

- For extremely small products, it takes time to set up the pickup device.

- We plan to modify the pickup device for such products to a method that does not take time to set up.

General Cam-type Automatic Lathes

-

The spindle-moving Cam-type automatic lathe moves the spindle in the longitudinal direction

and the cutting tools in the radial direction by a mechanical structure called the "Cam."

- The amount of movement is determined by the shape (step difference) of the "Cam".

- The speed is determined by the shape (gradient) of the "Cam" and the rotation speed of the camshaft.

- Therefore, we design and manufacture cams for each product and determine the rotation speed of the camshaft.

-

There are two types of cam-type automatic lathes.

- Spindle movement type

- The spindle moves in the longitudinal direction.

- The cutting tools moves in the radial direction.

- Spindle fixed type

- The spindle does not move in the longitudinal direction.

- The cutting tools moves in the longitudinal and radial direction.

-

The rotation speed of the spindle remains initially set by the operator.

It cannot be changed during automatic processing. -

The rotation speed of the camshaft remains initially set by the operator.

It cannot be changed during automatic processing. - With a cam-type automatic lathe, basically only round cutting is performed.

Advantages and Disadvantages of general cam-type automatic lathes

- --- Advantages ---

- Simple parts have a short machining time. (The production time of 1 piece is 2 seconds ~)

- --- Disadvantages ---

- It takes time to change the settings.

- Screw thread be manufactured with only the dies (or tap) of threading tool.

- Dimension adjustment of 1 μm is also difficult because it is adjusted by turning the mechanical dial.

- It is difficult to hand down the technique because there is a part that requires the elements of craftsmanship.

- For small parts, even if they are collected with a parts catcher, it is difficult and time-consuming to separate the parts and swarf.

- Very small parts tend to have low recovery rates.

NC-type Automatic Lathes

- NC-type automatic lathe is a numerical control type automatic lathe.

- CNC-type automatic lathe is the Computer Numerical Control type automatic lathe. Basically, both NC-type automatic lathes and CNC-type automatic lathes are the same.

- The NC-type automatic lathe moves the movement of the spindle in the longitudinal direction and the movement of the cutting tools in the radial direction by the servo motor. The amount of movement and speed are controlled by the process program of computer. Therefore, we design the process program for each products and input it to the computer. Various products can be manufactured simply by changing the process program.

- In recent NC-type automatic lathes, in addition to round object cutting by rotating the spindle, end mill cutting by stopping the rotation of the spindle can be performed by computer control. NC-type automatic lathes are capable of additional machining such as D-cutting, horizontal hole machining, horizontal tap machining, etc.

Advantages and Disadvantages of NC-type automatic lathes

- --- Advantages ---

- Setting change time for making different products is short and easy.

- Screw thread can be manufactured with the dies (or tap) of threading tool, or chasing process with the threading bite.

- Dimension adjustment of 1 μm is also easy because the amount of movement is corrected by the computer.

- There are few places that require the elements of craftsmanship, and it is easy to hand down the technique.

- --- Disadvantages ---

- Even simple parts have a relatively long machining time. (5 seconds / piece ~)

- For very small parts, even if they are collected with a parts catcher, it is difficult and time-consuming to separate the parts and swarfs.

- Very small parts tend to have low recovery rates.

Spindle Moved type and Spindle Fixed type

It is divided into the following two types depending on whether the spindle moves in the longitudinal direction or is fixed.

This applies to both Cam-type automatic lathes and NC-type automatic lathes.

- Spindle movement type automatic lathe (Petermann type)

- Spindle fixed type automatic lathe (Direct-chuck type)

In other words, the types of automatic lathes are subdivided into the following five types.

- Spindle movable type (Petermann type), Cam-type automatic lathes of microcomputer-controlled

- Spindle movable type (Petermann type), Cam-type automatic lathes old-fashioned

- Spindle movable type (Petermann type), NC-type automatic lathes

- Spindle fixed type (Direct-chuck type), Cam-type automatic lathes

- Spindle fixed type (Direct-chuck type), NC-type automatic lathes